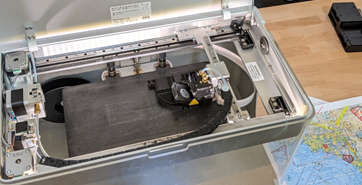

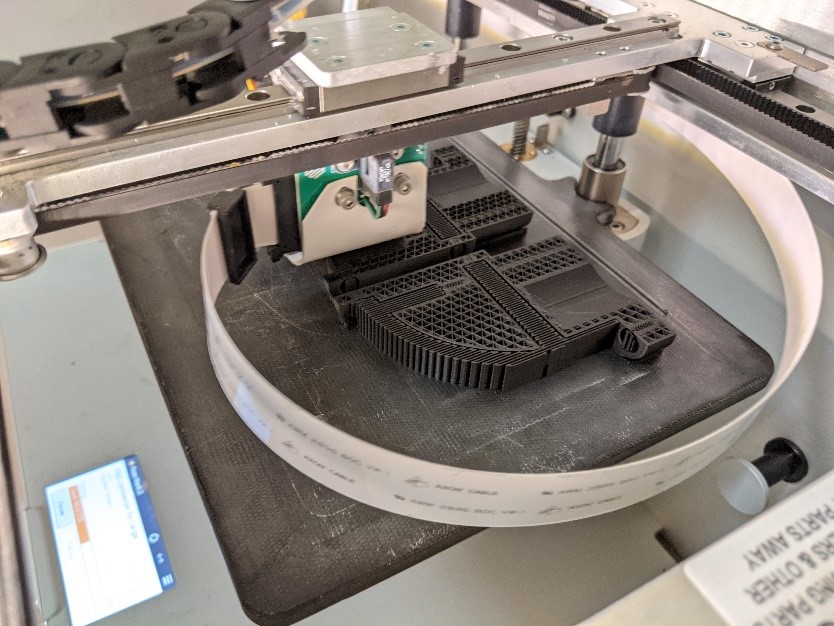

Fuse used its native 3D printing capability to rapidly prototype and solve a pop-up hardware issue. This issue was identified during local flight-testing of an integrated communications pod. The Fuse hardware team designed and printed cable backshells to fix a connector orientation issue at the last minute of flight testing. The quick-thinking and skilled engineering of the team ensured that flight testing was able to continue with minimal schedule slippage.